Garages and Durafleck 5000

The showroom quality floor you've always wanted

Over the coming weeks, I plan to outline our different products here in this blog.Seeing as we've started this year with a number of garages, I thought I'd begin this series with a few of them and our Durafleck 5000 product line.

We can apply any one of our different products to a garage floor, but I usually recommend the Durafleck 5000 system for its ease of cleaning, resistance to chemicals and obviously visually pleasing, granite-like appearance. Like many of our other products, it is great in other parts of the home and commercial areas as well. Kitchens, basements, hospitals and workshops can all benefit from this durable coating. Its available in about 30 different standard color combinations, but custom colors are available upon request as well.

Monk Seal Facility. Dark Grey Binder and Coal Chips.

The application always begins with clean bare concrete. Where we can't acid etch, we mechanically abraid with vacuum assisted grinders to not only remove any paint, grease or contaminants, but also to open up the pores in the surface of the concrete. This maximizes our potential for a mechanical as well as chemical bond with the existing concrete. Cracks can be fixed by a number of different methods, which I'll likely get into in another post. The repair typically coincides with the severity of the crack.

I should also mention that quite often, we find moisture along the seam where the garage and driveway meet. More often than not, contractors neglect to install a moisture barrier on exterior concrete. This creates a situation where moisture can migrate up to the surface, pushing the salts and chlorides with it. Fortunately we have a treatment for this, that creates a hydrogel membrane inside the slab and prevents the efflorescence. I'll go more into depth on this subject in a later update.

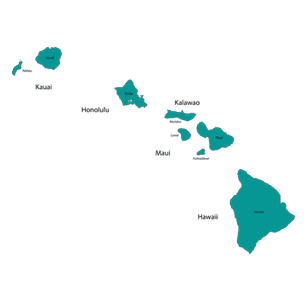

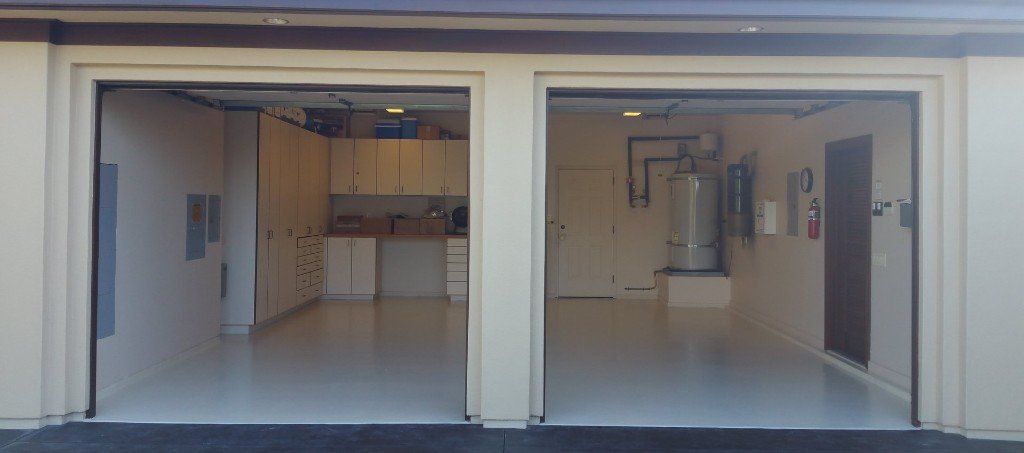

Mauna Lani Garage. Tan Binder and Buff Chips

Once the area is cleaned and masked, the application goes down in 2 stages. Day one, we apply the binder and flakes. The binder is rolled out and the flakes are shot using compressed air to get an even distribution. The look is far more uniform than say broadcasting by hand. We allow this coat to cure over night. Day two, we sand and sweep the floor to remove any loose chips, then we apply 2 coats of industrial grade, clear urethane sealer. Once cured this stuff will stand up to gas, oil, paint thinner, MEK and many other common chemicals.

Clean foot traffic is allowed the next day. Furniture and vehicles can be placed in 4 to 5 days. Low odor sealer options are available as well. You can find more pictures of the fantastic Durafleck 5000 system and more in the "Our Work" section above or at our corporate website here http://www.designcti.com/PhotoGallery.aspx. We have dealers all over the country and world. Feel free to leave any questions in the comments.I'm happy to share more pictures, technical data or before and afters.Call Concrete Technology of Hawaii inc. today for a Free Estimate 808 324-7600

Big Island Carbon. Medium Grey Binder and Coal Chips