Stone Classics

Custom Stone Finish

This week we have Concrete Technology of Hawaii's Stone Classics System. This one is similar to the Acrylistain system in its application with some differences in the coloring techniques. We utilize the same materials as the previous 2 systems; Hallmark and Acrylistain, so once again you get all the benefits of our polymerized acrylic concrete coatings without the cost and headaches of actual stone. All of CTi's colors are available as well as custom colors so we can compliment some of the colors in and around the home or business or we can come up with something totally unique and custom. Twice the strength of standard concrete and resistant to UV, fade, chemicals and staining. This alternative to stone stands the test of time.

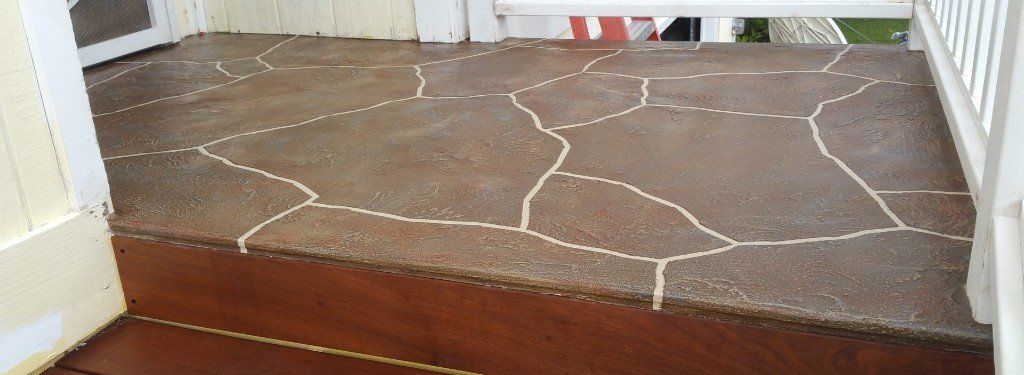

Kailua-Kona Lanai. Dark Grey Skim with Desert Beige and Charcoal.

Starting with the demolition phase. This includes grinding off any existing coatings or contaminants, removing damaged areas of the slab, grinding open cracks or even chiseling out grooves to install steel staples. Every project is a little different. That is why we offer free estimates to get an on-site look at the specifics of every project.

Preparation is the next phase. This includes repairing of cracks or damagesd areas, cleaning; including pressure washing, acid washing and neutralizing. Masking is a big part of what we do as well. We always want our jobs to turn out clean and our impact on our customers surroundings to be minimal. It always boggles my mind to see the carelessness of some other contractors when it comes to simply masking off a project to minimize over-spraying and painting. Some paper, tape and a little bit of extra effort go a long way and we at Concrete Technology of Hawaii take a lot of pride (sometimes bordering on OCD) in making sure we don't make a mess.

Mauna Kea Driveway. Black Skim with Desert Beige and Charcoal.

Efflorescence is always a concern here in Hawaii. I will be going over this in depth in a future update and I've touched upon it in some of the previous posts as well, but efflorescence is essentially moisture migrating from under the concrete slab to the surface. Should we find evidence of moisture and/or hydrostatic pressure, we can address this in a few different ways, but long story short, we waterproof the slab and get ready for application.

At this point, everything should be repaired, clean and masked. It's application time. Much like the previous two systems (The Acrylistain System and The Hallmark System) we start with a skim coat of our polymerized acrylic concrete in any color we like. This coat ends up being the grout color for our pattern. While most of the time we employ a random stone pattern, we can do any pattern or border such as tile, slate, etc.

Trinity Church Hilo. Dark Grey Skim with Sandstone Texture, Desert Beige and Nat Grey Highlights.

Once the skim coat has had some time to dry, it is rock mopped to smooth any rough edges, swept and blown clean. Now we can apply the pattern using filament tape in 3 available sizes (1/4, 1/2 and 3/4). Stencils are available as well, though most my customers and I prefer the customizability of doing it randomly by hand. This way we can make the stones any size and shape we like. I've even been asked to make a stone in the shape of the Big Island for example.

Waiamea Walkway and Entry. Beige Skim with Desert Beige and Dark Grey Highlights.

After the pattern tape gets laid out, we apply the texture coat. Again, we can use any color in the catalogue or even a custom made color, but by using a hand troweling technique, we can achieve a stone like texture. This is the same troweling technique utilized in the Acrylistain application. This coat must be allowed to dry before moving on. Once the texture coat is dried, we use a flat scraper to even out the texture and remove any sharp or loose points.

Kailua-Kona Lanai. Black Skim with Charcoal, Desert Beige and Natural Grey.

Once the texture coat is ready to go, then its time for the fun part. The color in this application is actually applied with sponges. We typically use 2-3 highlight colors in layers to achieve the tone we're looking for. We start by rubbing color into the low parts of the texture and finish by just hitting the high points in the texture with our final highlight color. The tape can be lifted before or after the coloring to expose the pattern.

Sealing phase is next. Just like our other systems, we have the same options available. Depending on the location and and amount of traffic, we can taylor fit a sealer option that is perfect for any project. We offer skid additives for extra traction or high gloss options for inside the home or business. Usually 2-3 coats of our clear industrial sealer is applied and allowed to dry. Low odor options are available for sensitivity to fumes as well. Clean foot traffic the next day. Furniture and vehicle traffic can return after 4-7 days depending on the sealer chosen.

Kailua-Kona Entry on Hardi-Backer. Sandstone Skim with Burnt Sienna, Desert Beige and Dark Grey.

Ask your Concrete Technology of Hawaii representative about the Stone Classics system around your home or commercial property. Other fine examples of the Stone Classics system can be found in the "Our Work" section above or on our corporate webstite as well. You can find those at http://www.designcti.com/PhotoGallery.aspx. CTi products and dealers can now be found in all 50 states and some 23 different countries. For your resurfacing needs in Hawaii call Concrete Technology of Hawaii for your Free Estimate today.